Access all areas (yes, even Adrian Newey's room) in the factory where the powerful machines are built.

Milton Keynes, the high-tech capital of motorsport

The most striking thing about the Aston Martin Red Bull Racing factory is how unobtrusive the building and its surroundings are. The town where the Formula 1 racing stable is located, Milton Keynes, is actually not known for anything except its huge amount of roundabouts. Agriculture dominates the landscape, and brown-white Herefordshire cows form dots over the green hills.

Only someone who is known in the area could tell you that this is really the high-tech capital of motorsport. Almost all Formula 1 teams are located here in the region, and not just the teams themselves. Also, the suppliers; the gearbox builders, the engine tuners, the transport companies are here. And rally teams, other formula teams, independent car builders, the list is endless.

The only real visible reminder of the importance of this region for global motorsport is the legendary circuit built here on an old airport from the Second World War; Silverstone. The first race was hosted here in 1948 and since then the backdrop for the Formula 1 British Grand Prix has been arranged, alternating with Donnington Park and Brands Hatch. Since 1987, Silverstone has been on the calendar permanently as the British Grand Prix.

But where, for example, the McLaren Technology Center is an incredibly impressive space lab designed by internationally renowned architect Norman Foster that you can only drive to through a checkpoint, Red Bull Racing is simply located on a meaningless industrial park. Apart from the Red Bull paintings on the wall - allegedly recently installed - and the vertically parked Formula 1 car hanging on the wall next to the entrance, there is no indication of the world-famous residents. The property could just as well be used by a distributor for photocopiers.

Inside at Red Bull Racing

The entrance to the building is already more impressive; the entrance is formed by a hedge of meter-high display cabinets filled with the countless trophies that the team rode together in recent years. Replicas of course, although not everyone knows that. A ram crack was committed a few months ago and a number of trophies were stolen to melt them down.

Although there is a large Red Bull gas station in the reception and a wall filled with even more silverware, there is not much to discover here either. Some merchandise is for sale in a corner, but that's it. To find out where the action takes place, you have to go through a back door and up a flight of stairs, but even there the interior is in no way as lab-like as you would expect.

There is a fairly finished carpet in the hallway and the R&D department is located in a large office garden with fluorescent tubes in suspended ceilings. And there are computers. Many computers. A quick count taught me that there are about 15 rows of fifteen desks in the room, subdivided into four-leaf clover-shaped cubicles where people are sitting behind old flat screens computing. An average mail-order company does not look very different. The only reminder that this is actually the factory of the world championship team are the small Red Bull refrigerators that can be found everywhere in the building.

Adrian Newey and his office

And of course, the brain force at work here is just a little bit different. While visiting the factory in Milton Keynes, I briefly had the opportunity to peek into the room where the words "Chief Technical Officer" are written. Adrian - The Legend - Newey himself was working. Sitting at his computer with his huge design desk behind him, ready for use. Newey's career is as illustrious as long, and with ten constructor championships to his name, he is the most successful yet active technical boss in Formula 1 right now.

After his debut at Leyton House-March in 1989, he climbed until he really began to gain legendary status as Williams' technical boss in the mid-1990s in the years that they still dominated Formula 1. He then went to McLaren, who, under his leadership, came back to the top until Red Bull hijacked him so that the team suddenly also won world championships. Yet you wouldn't say that when you see him at work.

His office is furnished with almost no interest, with large piles of paper in the windowsill and a silly lava lamp on his desk. The only thing that really sets his office apart from all the other offices is the huge design office, on which he apparently still works out his ideas.

The factory

Yet one floor below it really becomes clear that this is not a normal office. In a large, open space filled with large workbenches and large rolls of cables, young and old men work in team uniforms, with soldering irons and unrecognizable tools in their hands-on parts that together form puzzle pieces on that one powerful machine: Formula 1 car. Here racing parts are made in 1 huge garage. And not just any parts - this is special in every possible way. Electronics are essential for Formula 1 cars; without electricity, the engine will not even start. And here, in the electronics area, all sensors, cables, switches and even the smallest buttons on the handlebars are tested and connected.

In the pain room, four people work full time here and in recent years, I am told, a lot of work has been done invisibly. Thanks to new paint compositions, a weight saving of no less than twenty percent has been achieved here since 2005. It is not uninteresting that everything you see on the car is sprayed directly on it; stickers are no longer used at all. The precise composition of the paint is, of course, a secret, but from close by it most closely resembles matte plastic.

The space next to it is reserved for wind tunnel tests and calculations for scale models. The FIA has, of course, devised all kinds of rules to limit wind tunnel use as much as possible. The FIA also checks its use by requiring inspection of wind tunnel plans, power consumption, etc. It only becomes very special when you see the space next to it, which is filled with a number of 3D printers. Parts and entire prototypes are printed here, which can then be tested in the wind tunnel. Although I am told fairly quickly that it is not officially 3D printing, stereolithography. That you just know.

The control centre of Red Bull Racing

Elsewhere in the building, there is a space that - as I have been told by someone who has been there - is about the size of the Space Control Center in Houston. What I know for sure - because I saw it myself - is that it really looks like the Space Control Center in Houston. This is what Red Bull Racing calls its AT&T Control Center. The space is classified as a wide amphitheatre with rows and rows of computers that you can see on the pit wall and that are all focused on a huge screen on which as a mosaic all kinds of different images of a circuit can be seen thousands of kilometres away.

This Control Center was, of course, empty at the time of my visit, but especially during the free training sessions on Fridays of race weekends, there seem to be top crowds here. And the numbers are incredible. A physical connection is always made to the data centre on the circuit, and around 400 GB of data is exchanged during a race weekend. All data from all dozens of sensors in the cars can be seen in Milton Keynes within 0.3 seconds (although the data is stored elsewhere - in a secret high-security basis).

In one row, engineers are only busy analyzing the competition. What complaints, strategies, ideas and tactics they discuss - everything is monitored. The men of aerodynamics are in the next row. The colleagues of vehicle dynamics are in a different row. All circuit data is constantly viewed. And yes, even the employees of the social media team are in this room to follow everything as well as possible. Now you know where all those clever Red Bull tweets come from!

Anyone who sees this space with their own eyes suddenly realizes why Formula 1 has occasionally become a high-priced procession. All data is constantly collected by computers in order to be able to weigh the optimum result against the least possible risk. It also shows how cunning Formula 1 teams deal with rules and how they always work sharply; this entire data centre was built because teams can take a maximum number of people to the circuits. And you also understand why FIA boss Jean Todt is slowly starting to philosophize harder about less interference with data. Very little is decided on gut feeling, everything is computer controlled - the drivers seem to be remote-controlled robots. Although they are fortunately not that far of course ...

The heavy machine work

In an adjoining hall, it suddenly becomes clear again that no Chinese cities are being checked here, but that we are here for the most high-tech motorsport on earth. When a large garage door rolls open, the real heavy machine work is suddenly revealed. Here it smells of oil, and grease, and steel that is processed, like it smells in car factories or even the garage around you. And the numbers are impressive. Except for the gearbox, the engine, the brakes and of course the tires, all parts are made here by Red Bull Racing itself. More than fifty different types of steel are used in this garage alone.

The plant is in constant use, open 24 hours a day. In total around 10,000 parts are made per car per year. If Gasly had finished at Red Bull last year even more. Work is also carried out here during race weekends. It often happens that a new part is not finished before the team goes out, or that a part is flown in for other reasons. In that case, someone who happens to be at the factory - receptionist or mechanic, it doesn't matter - is put on the plane to the circuit with that one part on the plane. "The race is the only deadline we have," says an engineer.

TAG Heuer, the partner of Red Bull Racing

I came to the Red Bull Racing factory at the invitation of timing partner TAG Heuer to see with my own eyes what that partnership actually entails. And to understand that, we have to go back into history for a moment. Not to the zeroes or to the nineties, or even the eighties, when TAG Heuer was a partner of McLaren, but farther back, all the way to the fifties, the years in which a young boy Jack Heuer became intrigued by car racing, like many boys before and after him. The only difference between him and those other thousands of boys was his last name: Heuer was the great-grandchild of the founder of the family business who then only bore his last name, without a TAG.

And for those who now think: oh dear, this will be an advertising story, rest assured. This article is a journalistic production for which no payment has been made. A story that delves into how TAG Heuer and motorsport became eternally connected. And that may well be told because it shows that the best connections are made when they are organic and not conceived in a marketing plan.

Well, back to 1957. Jack Heuer was not really active in the company of his ancestors at the time, but he had a preference for racing. In his autobiography, Heuer describes a visit to the Monaco Rally. When he walked past the cars after the races, he suddenly noticed something. Almost every car he peeked in had a stopwatch from the company he was the offspring of. A large Heuer stopwatch adorned every dashboard. Motivated by that idea, he went back to Switzerland but did not immediately do anything with it.

Later he also visited the legendary Carrera Panamericana rally, where he saw more Heuer dashboard clocks passing by. When he also started trying to race himself, and by now he had finished the technical university, he wanted to make a watch that was more useful during races. Initially he tried that with the Autavia, but that watch didn't really catch on. Later he created what would later prove to be his masterpiece, the Carrera.

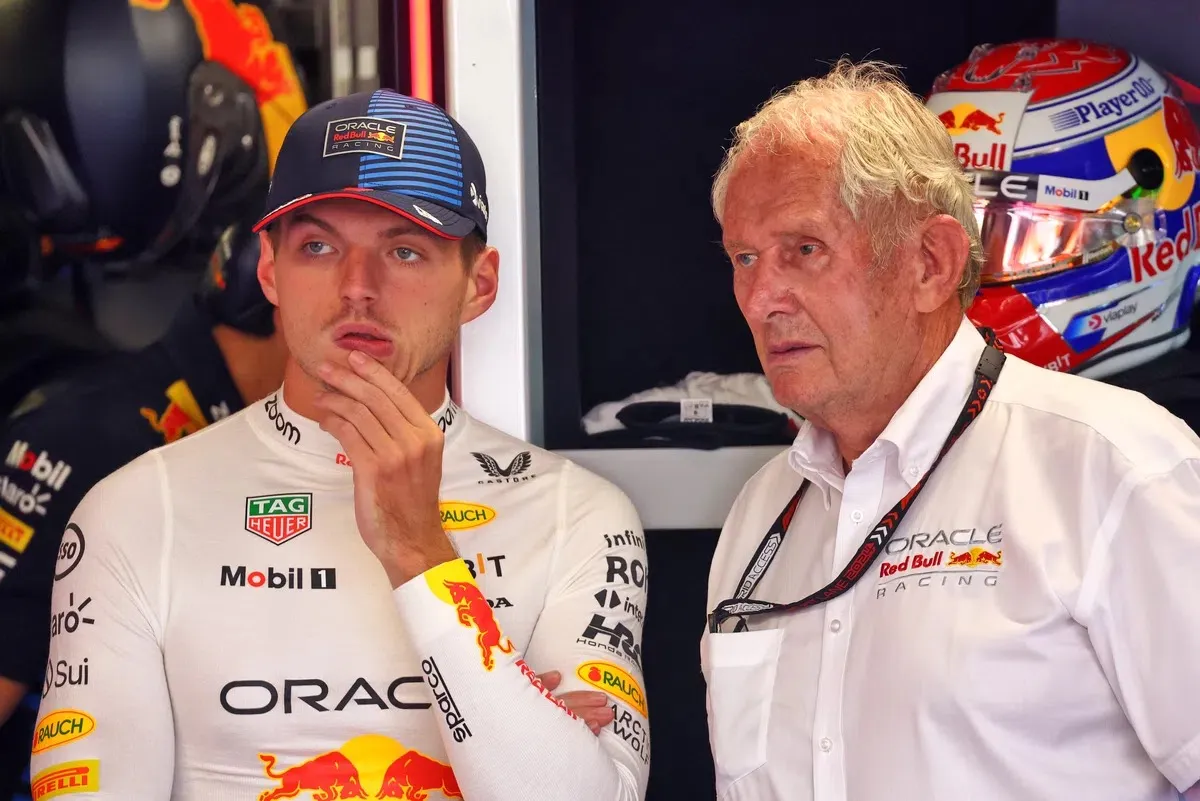

Heuer was technically strong, had a good team behind him, was averse to excess and very no-nonsense in his design approach and made a watch that is now on the market more than fifty years later. And that is supported by Max Verstappen - the man who is at least as no-nonsense, technically strong and stubborn as the maker of his watches. It can't be a coincidence.

Heuer and Ferrari

Later, in the early 1970s, Heuer started playing with the idea of entering Formula 1. Via-via he heard that a competing brand was discussing with Clay 'Crash' Regazzoni, the charismatic Swiss driver who was driving a Ferrari at the time. Heuer decided to take a different approach. He heard from another source that Enzo Ferrari had a problem: Il Commendatore did not trust the French timing crew at Le Mans. He was looking for an opportunity to reliably time his Ferraris. Heuer contacted Maranello, where he came into contact with Ferrari's number 2, a man whom Jack Heuer describes in his autobiography as "a neat, well-developed young man, impeccably dressed and clearly of good origin"; Luca di Montezemolo.

The stories Heuer can tell about his dealings with Ferrari are as beautiful as you hope they are. How the Italian signs his papers with a purple fountain pen, how he turns every dime ten times, how he sits in a darkened room somewhere in the factory, with only one spot on focused on a portrait of his deceased son Dino. But the best story I came across in Heuer's biography is a wonderful way in which the partnership between the two brands finally came about.

Heuer sent his electronics man to Maranello, a man who also spoke excellent Italian. The parties started working together, but Enzo Ferrari nevertheless refused to pay for the equipment. He wanted to be able to use everything for free. Heuer himself once again drove to Maranello to meet Il Commendatore and finally, a deal was made: Heuer was allowed to place his logo prominently on the cars when he would take the timing for Ferrari. But after some extra hassle, Ferrari came up with some additional wishes. "Drivers are so expensive these days," the Italian grumbled. "You have to sponsor them too." And so it was that Jack Heuer offered his watches - golden Carreras - to Regazzoni and later also to Lauda.

Heuer later installed all the timing infrastructure on the Fiorano circuit. And so it happened that TAG Heuer was the first watch brand to have such an intimate collaboration with a Formula 1 team. In the 1980s, when the Swiss watchmaking business did not go so well and the Luxembourg investment party Technologies d'Avant-Garde (TAG) took over the family business, the cooperation with Ferrari was also lost. Shortly thereafter McLaren would come - a partnership that lasted until two years ago.

It's all about timing

As I walk through the Red Bull Racing factory in Milton Keynes, I notice how the personalities of both brands fit together. Both brands are innovative, open-minded and dare to make sense. In that respect, TAG Heuer does indeed fit better with Red Bull than with its previous partner. I ask the spokesperson of the Formula 1 team what exactly he gets out of the collaboration with TAG Heuer. Whether something is actually being contributed to each other, or whether it is purely cosmetic. He honestly replies that the main goal for TAG Heuer is brand awareness, but that there are many natural interfaces in both branches. Information is everything in Formula 1. Timing is everything in Formula 1. And the car is - despite all electronics - still a mechanical object.

All those things also apply to watches. TAG Heuer was the first team to introduce electric time measurement in sport, and has been involved in racing from the very first moment cars were invented. The spokesperson tells me how both brands have actively started looking for ways to make the collaboration ever closer. One of those activities was a visit from a number of Swiss engineers to the Red Bull factory.

At a certain point in that tour, they arrived in the room where the pit crew was busy practising the pit stops. One of the employees of TAG Heuer asked: "how do you actually measure the time for these pit stops?" The answer: "just with a stopwatch."

This idea travelled back to Switzerland and a short time later the mechanics in Milton Keynes received a new, electronic timing set. The following year Red Bull would - coincidence or not - break the world record of the fastest pit stop of all time, allowing Max Verstappen to make that race the difference. Formula 1 is a sport that is decided on the smallest margins - and time is the determining factor.

People make the difference

Now that the new racing year is coming, the Red Bull Racing factory is, of course, running at full speed. This is the epicentre of all the activity that you will see later on the course. But what my visit to Milton Keynes has brought me is a much deeper understanding of what it takes to get a team to perform at the top of its margins every race. When you see such a factory inside, you really feel that what we see on TV is really just the tip of the iceberg. Whoever sees that, understands why every team boss actually finds the constructor's title much more important than the driver's title.

And what is special about Milton Keynes is that it still feels like a car factory. It smells of oil and steel and machines are running at full speed to produce parts. Computers outline the framework in which the cars can perform, but ultimately it is human hands - at the wheel or in a CNC machine - that make the difference. And that is quite reassuring.

This article originated on the GPBlog.com/nl website - written by Gandor Bronkhorst

Read more about:

Popular on GPBlog

1

Why Verstappen is a top favourite to win the Saudi Arabia GP

1389 times read

2

Croft gets told to stick to commentating by F1 champion, Verstappen

822 times read

3

Saudi Arabia provides updates regarding "New" F1 team

558 times read

4

Verstappen leaving Red Bull? Franz Tost sees the driver going to this team!

550 times read